A Danish-Norwegian research group has designed a metal-based monolithic solid oxide fuel cell (SOFC) that is claimed to be suitable for transport applications. The scientists explained that SOFCs are generally utilized for stationary applications, in particular with combined heat and power systems, thanks to the high temperature at which they can operate. These devices, however, are generally considered less suitable for vehicles due to their lower power density and the limited thermal cycling robustness of their ceramic anode.

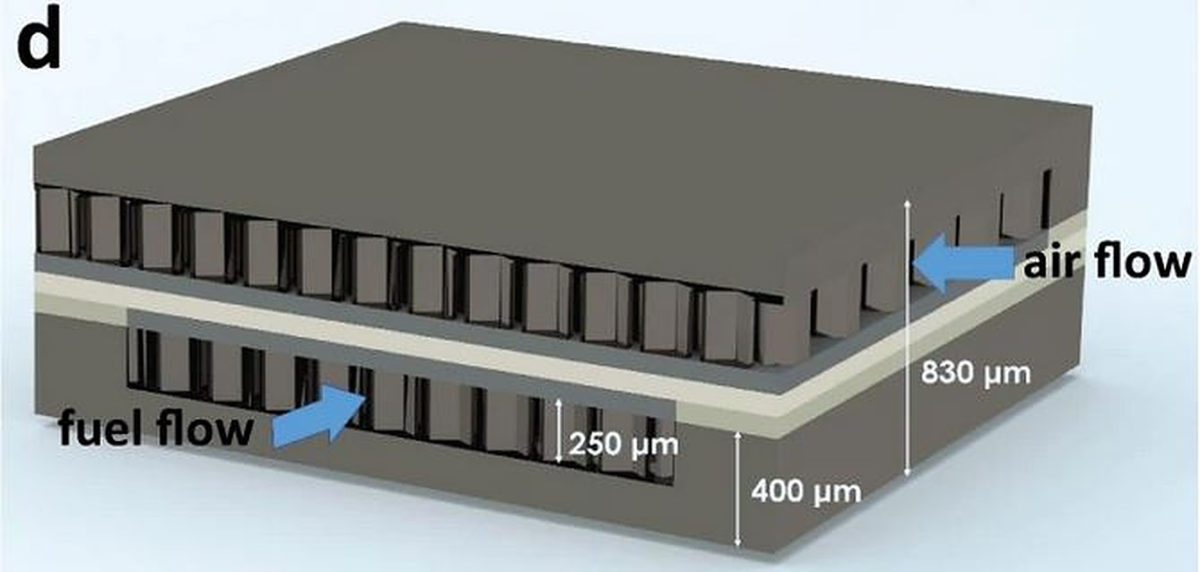

In the proposed fuel cell configuration, the ceramic anode was replaced with metallic interconnects. “The monolith concept integrates the cell support, gas channels, and the interconnects into a single layer, thereby reducing the stack height by a factor of 2–4,” the researchers explained, noting that the metal-based monolith stack is significantly cheaper than a conventional stack. “This considerably increases the volumetric density and specific power of the stack, which are important parameters considering the space and weight constraints in vehicles.”

Furthermore, the high metal content of the SOFC is claimed to lower temperature differences across the stack and offer more robustness to fast thermal cycles during operation, which the scientists said could be important when combining the fuel cell with electric batteries in a vehicle. “Previous work on monolithic SOFCs designs were reported by Saint-Gobain, which developed fully ceramic monolithic SOFC stacks, and by Argonne National Laboratory, which designed metal-supported SOFC stacks (‘TuffCell'),” the research group stated. “However, our concept of metal-based monolithic SOFCs comprises several significant differences when compared to the one developed by Argonne National Laboratory, such as the processing techniques to integrate gas flow channels, the electrode materials and thicknesses, and the concept of integrated seals.”

A monolith SOCF with an active cell area of around 18 cm2 was built through four processes – tape casting, lamination, co-sintering, and catalyst infiltration – which the scientists described as common techniques utilized in fuel cell manufacturing. The device was found to have an open-circuit voltage of 1065mV and a power density of5.6 kW/L, which the researchers said are on par with the best performing fuel cells based on ceramic anodes. ” We speculate that this design, or similar, could enable large-scale production of electrified transportation powered by fuel cells with considerably increased range, decreased charging times, and lower cost,” they concluded.

The fuel cell tech is introduced in the paper Production of a monolithic fuel cell stack with high power density, published in nature communications. The research team includes academics from the Technical University of Denmark and Norwegian research entity Sintef.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Es una publicación muy importante sobre cómo usar la energía del hidrógeno en las celdas de combustible para uso automotriz un abrazo…